When I was in Chicago, I met up with Kimberly FitzSimons of Daily Sip Studios, a fellow Minted designer and letterpress printer. We've been email friends for a couple of years, but this was our first time to meet in person. When I knew I would be in the city, we made plans to get together, and she suggested that we go to her studio and print some stationery and business cards for Palm Papers. I've been wanting to learn more about letterpress printing and this was better than any small class that I could have taken. On Saturday morning, Kimberly picked me up at my hotel and we drove to her studio where she keeps her press. She has a Vandercook SP-15, which was built in the early 1960s. It was a big machine, but wasn't as intimidating as I thought it would be once we got started.

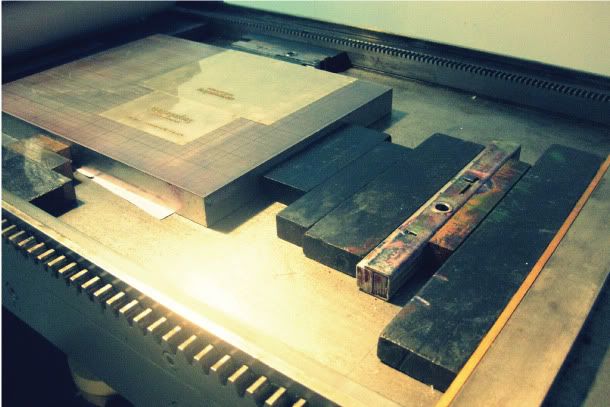

Before I got there, Kimberly made some plates for my business cards and stationery. They have adhesive backers so when you lay them on the press, they won't move. We lined them up so that we would fit a note card and a business card on each side of the paper.

Next, she got started mixing the ink. I brought a swatch with me and we picked out the closest color from a Pantone swatch book and started mixing based on the formula. I think the inking process was the most interesting part. A little ink goes a LONG way and it appeared so much lighter on the rollers than it printed. It looked pastel pink on the rollers, but ended up printing a perfect coral hue.

Getting the right color is a trial and error process, so we started out lighter and added a little color directly to the rollers as we went. After a few test prints, we were pleased with the color and were ready to start printing!

First, I inked the plates by taking the handle and rotating the rollers over them. Then, I lined up the paper on the left and attached it to the grips. Rotating the handle pulls the paper over the inked plates to make the impression. After you've rolled it all the way through, you remove it on the other end and move the rollers back to the left, re-inking the plates for your next run.

Each sheet went through the press twice, printing a business card and note card each time. If we had used two colors, we would have had to clean the rollers, mix new ink and run everything through the press a second time. I can easily see why letterpress costs what it does. It is a lot of work - but so very worth it!

This experience really made me fall more in love with this type of printing. It is so beautiful and really is an art form. I can't wait to offer more letterpress in the future.

Thanks Kimberly for giving me such a fun experience and being so sweet and generous with your time! I loved it!